there’s a huge difference between art and craft, simply by definition. art is a search for beauty with no functional requirement. craft is the answer to a specific necessity. but there is a huge amount of crossover. art can be useful (though it often isn’t and there’s no need for it to be to be worthwhile — a fulfilling piece of art isn’t useful but it makes you incredibly happy and that’s amazing). more importantly for us, though, as makers who work in wood, craft can be beautiful. if you make a table and it doesn’t work, you suck. it’s not a table. it’s a work of art similar to a table. but a table has to hold stuff off the floor. a chair you can’t sit in? that’s not a chair. that’s just bad art.

there’s far more to it than just building something that works, though. there are myriad volumes talking about simply-functional furniture (i think the best is chris schwarz’ [the anarchist’s design book]). speaking of volume, there has been a generalized trend lately to turn that tendency to build ugly-yet-stable furniture [up to eleven]. and it’s a bad idea. that’s not what i’m particularly interesting in talking about today (my topic is something far more useful, i hope) but this is unwise for many reasons. for one, beauty is an important part of our human existence. it gives us pleasure. and, if we stop looking for it, stop accepting it and stop demanding at least a little form and aesthetic consideration in our days, we become a little less human, likely a lot less happy. the soviet era mirrors its brutalist architecture and the iciness that resulted from people walking around surrounded by concrete day-in-and-day-out. functional is important. very important. but it’s not the answer to everything. something must work flawlessly. but if it doesn’t speak to us, resonate with our sense of beauty, proportion, balance and appropriateness in the moment, it is lacking and anyone who tells you “good enough” is a model for fulfilling design is simply wrong.

that being said, we are woodworkers. we work with wood. but do we understand it? well, it’s an organic substance. how much can we truly know each individual tree? perhaps not all that well. we only spend a few minutes or hours with each of them and we’re not exactly taking it out for a cup of coffee. or a beer. well, unless your shop-time is very different from mine. and i suggest avoiding mixing the beer and the edge-tools. your fingers won’t be pleased by the combination. but we can certainly get a deeper understanding of the nature of wood in general.

first, we have to stop ignoring the fact that it was (quite recently) alive. and that these trees aren’t like the vegetables on our plates and fruits in our snacktimes. they have long, complex lives, often far longer than hours. the tree you are turning into a table might have been planted long before the wars your grandparents fought in by someone who was dead before your parents were conceived. that wouldn’t at all be unusual. what has that tree seen, experienced, lived through? how many people climbed it, leaned against it, used it for shade who have now died? how many loves were consummated under its branches?

ok, maybe not that many unless it came from someone’s yard. but you get the idea. there has, in japan and korea as well as some parts of what is now america, for millennia been a tradition of venerating the spirit of a tree before and after working it. saying a prayer to the spirit or energy that gave it life, thanking it for its sacrifice then honoring it with the finished workpiece and offering it to the memory of the tree. you might not want to go through this ritual but i really think you should try it someday.

simply kneel on the floor of your shop before you start working on a new project, close your eyes and say a quick thank-you for the materials you’re going to cut into. you’ll be more careful and it will give you a sense of peace. when you’re finished, again, take a moment to recognize the role the tree played in what you have done — i mean, you couldn’t have made the piece without the beautiful growth of the tree. maybe bow, close your eyes, say a quick thank-you, light a stick of incense. i know this might sound silly but this ritual really does give me a deeper sense of accomplishment and connection to the craft.

second, though, we have to stop treating it like an alternative to plastic or metal. especially not like an imperfect alternative. like “i’d work with metal but it’s hard” or “i’d work with plastic but eww that hot-melt smell”. wood moves, shifts, breathes — it changes with the seasons as do we and that’s not an accident. we have selected a living material and it feels, if you do it right, like it’s alive. your table should feel warm to your hands. plastic and metal feel cold and dead. there’s no spirit, no life in them. but a wooden piece of furniture is a joy to see and touch every time. it feels like another life in the room. on a cold morning, i don’t want to have to sit at a glass desk with metal supports. touching those will be lifeless and freezing on my fingers. but the wooden desk invites my hands to rest on it. it’s not a shock to my body to connect with it — thankfully, i do most of my work on an ipad with a rubber keyboard and case because i dreaded first-contact with the cold aluminum of my laptop’s casing when i began work in years long ago before i made the switch.

if we’re going to do that, though, we have to embrace it like a lover. ok, at least like a good friend. perhaps best not to get all hot and sticky about your lumber. unless it’s maple. cause that’s often hot and sticky enough for us all, especially sugar-maple. just saying. the point, though, is that we have to know its strengths and weaknesses. how it will behave, what it looks like on its good and bad days. how it rects to what we ask it to do. over time, we learn these things about wood. and it’s fairly-predictable. not completely — it is, after all, a living thing and those are never wholly determined as i’m sure you’ve discovered if you’ve ever been in a relationship — or, for that matter, had parents and siblings. but it’s predictable enough for our purposes as craftspeople.

maybe you haven’t thought about it. but our wood has to come from somewhere. a tree. and how that tree has been treated determines so much in our procedure. that beautiful grain is the result of a tree having lived a tortured life. reaction-wood is hard to work with but it can be stunning when used with restraint and purpose in a finished piece. that’s not the majority of what we’re looking at when we go to the lumberyard, though. the real question is how to deal with the three main ways trees are turned into lumber and what those mean. somewhat what they’re used for but that’s really just a question of logic.

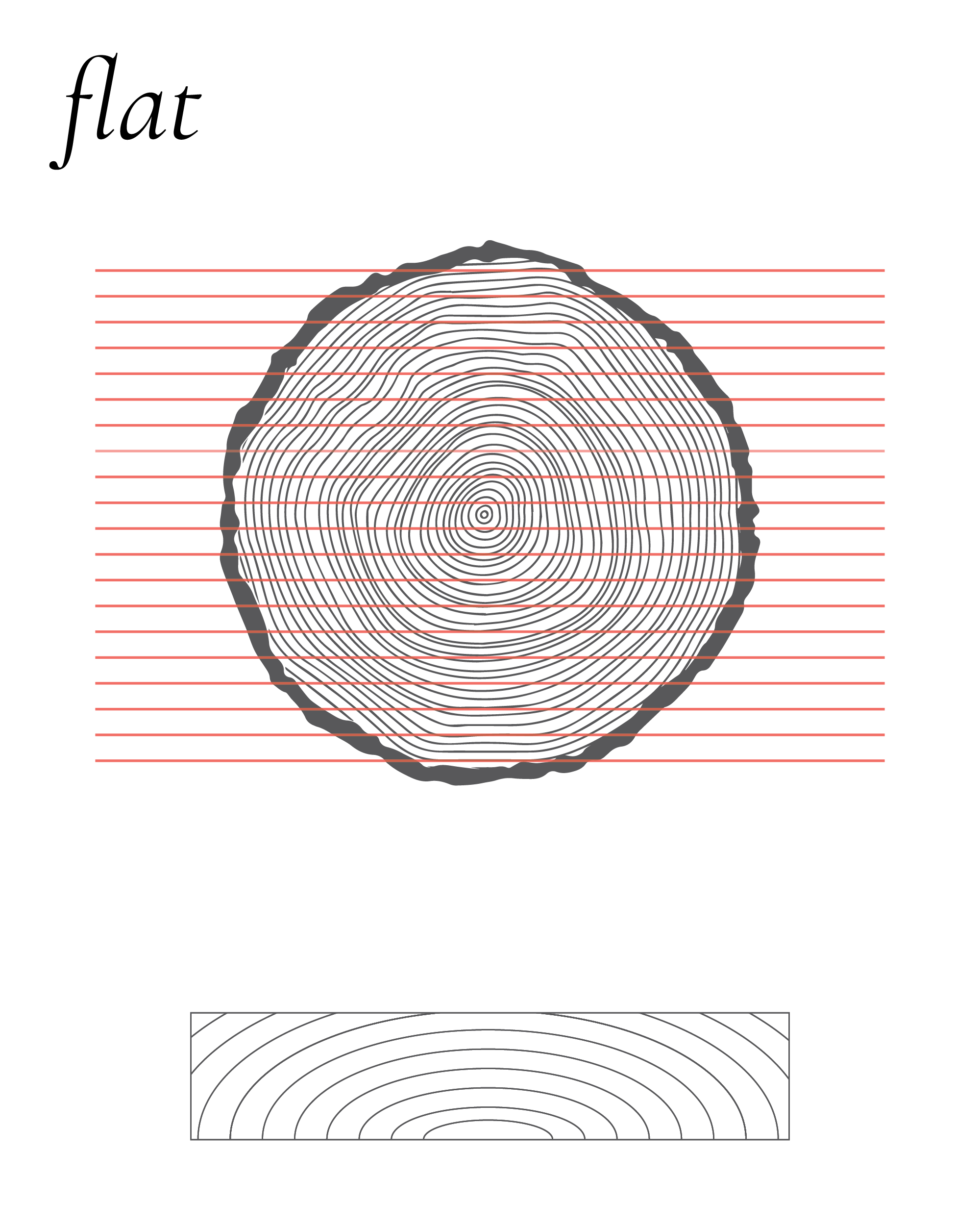

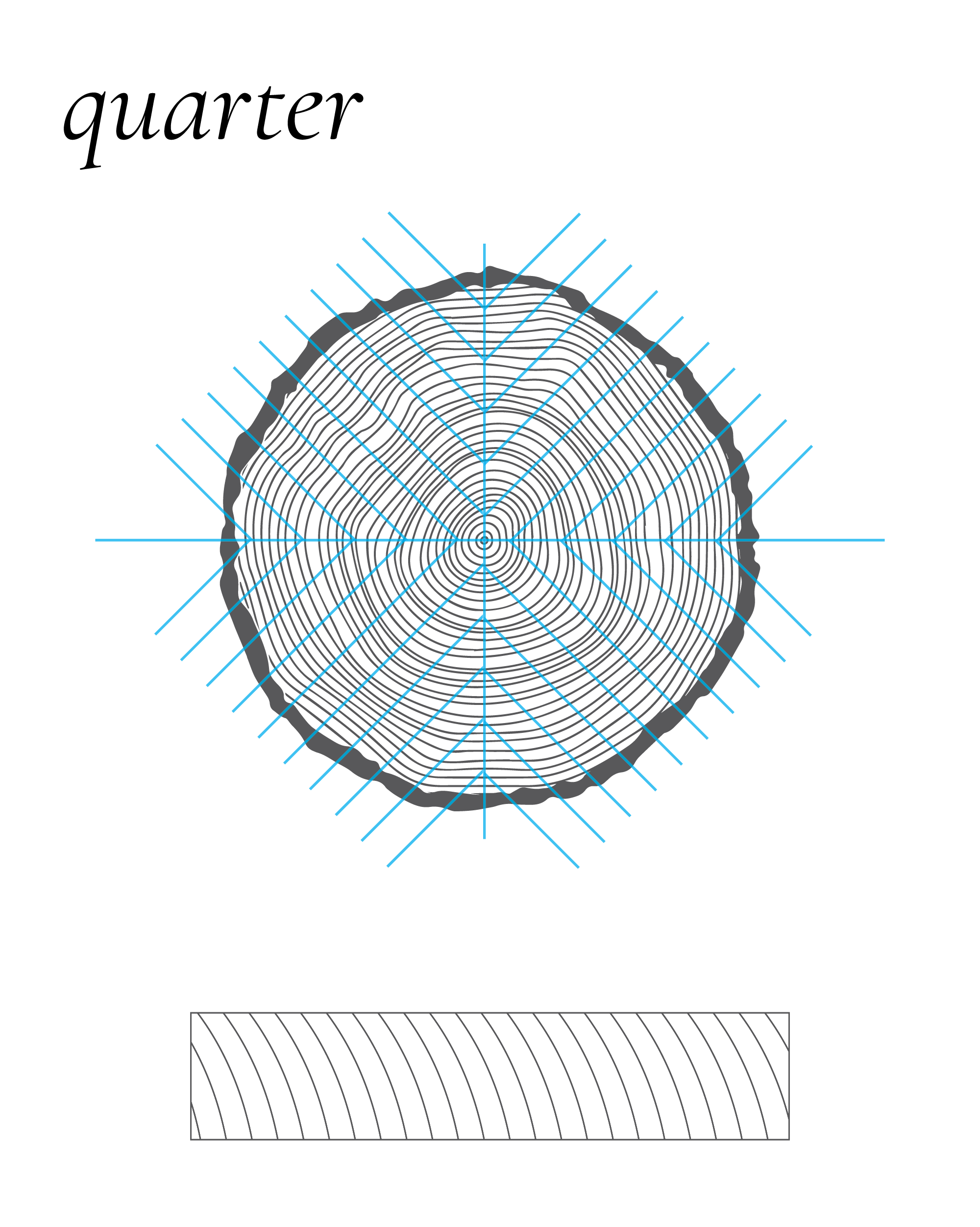

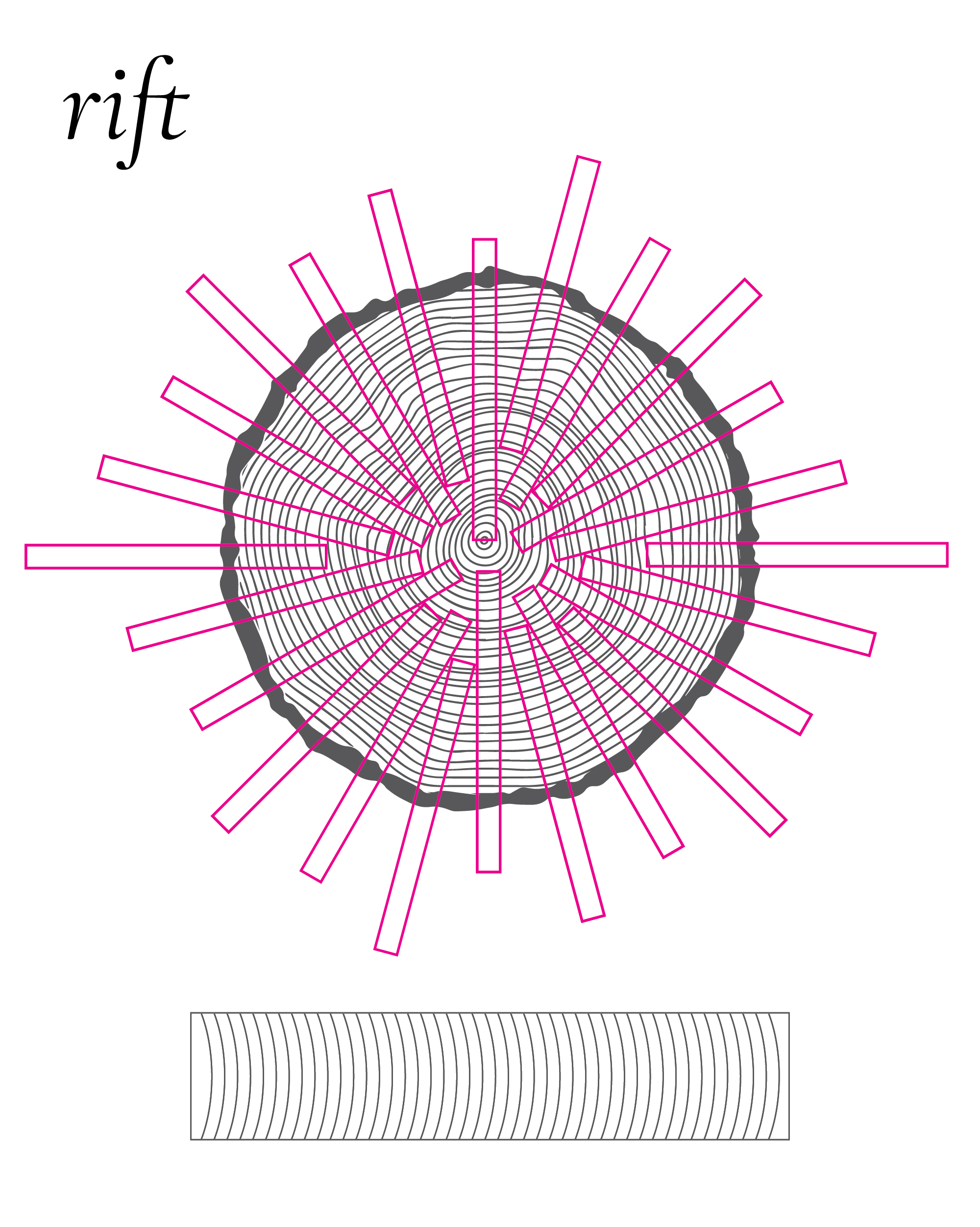

there are three main approaches to cutting a log into boards and each goes by many different names but the names i’m going to use are flat, quarter and rift. you’ll hear flat also called “plain” or “linear”, quarter called “bisected” or “cross-pattern”, occasionally even “x-cut” or “x-sawed”, and rift called “radial” or “perpendicular”. in softwood, you’ll hear “vertical grain” used as a term for both rift and quarter, which is beyond confusing but these words all show up and you’ll have to deal with them — linguistic variation is the plague of my existence and i suspect, as you learn more, will become at least a small nuisance in yours. we’ll start with the practical and move on to the result.

to flat-saw a log, you put it on a mill (usually a bandsaw or industrial — read, massive as all fuck — spinning blade but it can be done by hand or with a chainsaw) and cut it from one end to the other in thin slices. these can be as thin as maybe 25-30mm but tend to range from about 50 to 150mm and are the standard boards you see at the lumberyard. 90% or more of all wood you see in a store will be cut this way. it is by-far the most efficient use of material because the only wasted section is the center of the tree — and that’s not actually wasted as they turn it into large posts, though using them is … unwise, to say the least, as the center of a tree (the pith) will always crack. always. there’s simply no way to stop it. you can stabilize it and pretend and hope, pray and light as many sticks of incense as you like. let someone else mess with the pith. there’s plenty more tree where that came from. don’t waste your time.

but there are two other ways to approach that same tree. they’ll take a little more visual imagination, though. and i’ll include a few diagrams to make it easier on you to picture it. if you cut the tree right down the centerline then turn it 90-degrees and do it again, you’ll end up with four quarters (yes, that’s why they call it quartered wood). if you then take each of those and cut them at 45-degree angles to the center of the tree, you’ll end up with boards. there’s a bit more waste but the wood is far more stable because you’re no longer working quite as aggressively against the rings — if you want to see a board that’s going to move like crazy when it changes moisture content, pick something with huge cathedral patterns on its face. those are split grain-ring lines and that’s where things are going to warp and twist and bend every time the air gains or loses moisture.

the last way is the most wasteful but generally gives the best results. if, instead of cutting the board in quarters, you cut each segment more like pieces of pie or pizza then flatten them to boards, you’ll get lumber that exactly mirrors the grain-rings. each projects radially from the center (this is the hardest one to picture without looking at the diagram) — imagine taking a circle and drawing a line through the center (a diameter) then another from another point on its circumference, then dozens more, equally-spaced. now make those lines thicker. those are the boards when looking at the end of the log. each is a radius from the center. this is by-far the hardest thing to accomplish when actually cutting up a tree and it’s comparatively-rarely done. but it produces very stable wood that barley moves at all with the seasons — you still have to account for movement but the movement will be significantly less so you can aim for far tighter tolerances.

here’s a visual reference that should hopefully help to see where each board comes from, depending on its cutting-pattern, and what the result is on its two pairs of faces.

hopefully this will encourage you to take a few moments to contemplate the tree that was once alive and has now become the raw material for your (our, of course) craft. we must never forget we’re lucky to have an organic material at our disposal that is continually changing and adapting to its environment. sometimes we might complain it moves or changes color but really the whole skill involved in what we do is in understanding that constant breathing with nature it continues to do for centuries after its death. thanks for taking this time to explore “the nature of wood” with me. i know it’s a bit esoteric but i hope it’s been useful. may the spirits of the trees uplift you today. until next time…