if you cut a lot of dovetails, there is a tool you may be missing from your kit — a fishtail chisel. of course, this might be old news to you as most of the modern manufacturers make one. the problem is, as always, that they’re brutally-expense. but we’ll get to that in a minute. first, let’s talk about why you might need one.

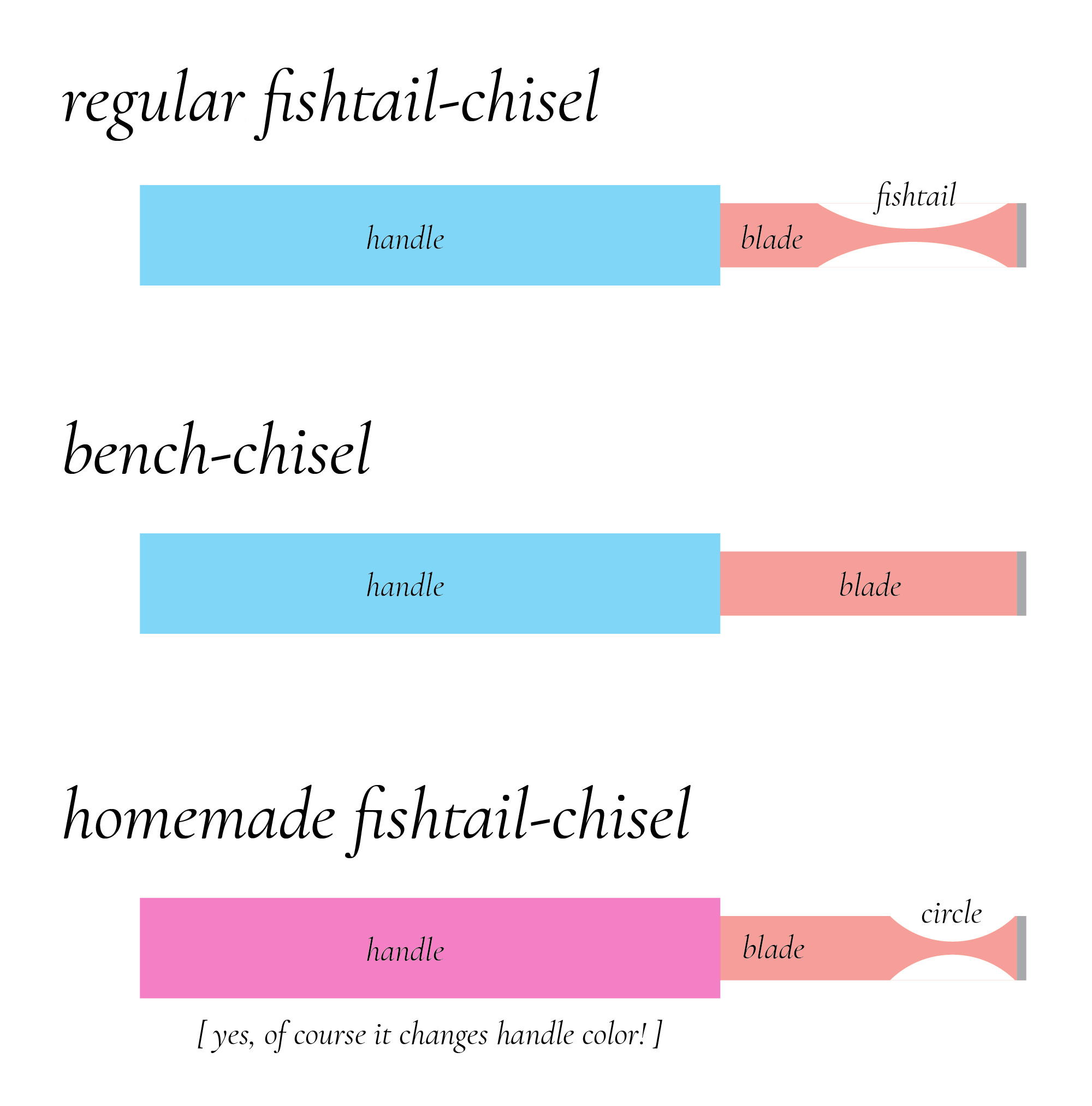

a fishtail chisel, as the name suggests, looks like a regular bench chisel of the same size but, instead of having a blade that’s straight along its length, it has two rounded notches cut in the side. this varies by brand, of course, but it looks vaguely like you pinched the chisel perhaps a centimeter behind the cutting edge and squeezed it hard enough to thin the blade to a small fraction of its full width. the effect of this is to make a chisel shaped like a very aggressive dovetail when viewed on its face.

of course, there are actually fairly few times when you need a chisel like this. if you cut a lot of through-dovetails, this isn’t an issue. a standard flat bench-chisel will clean the insides without any problem. but if you cut half-blind dovetails or any other angled-recessed joinery you’ll probably have noticed it’s difficult to clean the waste from the inside corners because the thickness of the chisel keeps it from getting close enough for the last tiny bit of paring — either from the edge or face direction.

what the fishtail profile does is allow the chisel to get close to that inside corner without the rest of the blade making contact with the angled portion of the joint — it’s designed specifically to allow undercutting, which is part of making half-blind joints.

this is realistically a single-use tool but it’s a very important thing to do to get your half-blind dovetails to seat properly and can save you a huge amount of time and frustration. what’s the alternative? well, there are two.

one is you can use a skew-chisel with a very acute angle. this will allow you to get in the corner but it’s far more difficult to do it with that sharp point. and, if you are cleaning both sides of a dovetail, you might find it easier with a pair of skew-chisels, one skewed in each direction. of course, if you’re buying new, commercial skew-chisels, this doesn’t save your budget anything.

the other is to use a long, flexible knife to trim the waste right in the corner. this definitely works but it’s easy to break a disposable knife this way or bend a non-disposable one. you’re realistically using a tool not very-well-suited for the task at hand.

but you’re in-luck. for a tool you only use for a few seconds when you’re cutting one specific joint, the nearly-hundred-dollar pricetag feels unreasonable. don’t get me wrong — i have no problem spending serious money on a nice chisel. veritas, lie nielsen and various japanese makers will certainly encourage me to part with vast quantities of my hard-earned currency. but for something i’m not really going to use much or often, i am very hesitant. and when it’s something that doesn’t even have to be good to be useful, i’m not really interested in cashing in when i can just have something far more useful for what i save.

the solution is to convert a standard, vintage bench-chisel to a fishtail profile. and this will take you only a few minutes with things you probably already have in your shop. you’ll need a drill (seriously — are there any woodworkers out there without a drill?), a dowel, some sandpaper, glue, a long bolt and a cheap chisel in your desired width. let’s get started.

grind your chisel but don’t bother to sharpen it. put tape over the edge because, even without being sharp, it’ll still cut you if you’re not careful. and i’m not that careful — if you are, you can skip the safety precaution but for ten seconds and a piece of tape i suggest your fingertips don’t need to bleed today. your choice, though.

grab a wide piece of dowel-stock maybe 40-60mm long and a bolt long enough to go all the way through your piece with at least 50mm sticking out the end. drill a hole through the center of your dowel — yes, be precise — if it’s not centered you’re going to have a nightmare when it comes to using it. put some quick-set epoxy on the bolt and shove it through the hole then let it dry. when that’s done, stick the shaft of the bolt in your drill and make sure it spins properly. it should unless you made a rather strange error at this point.

use your quick-set epoxy to glue coarse sandpaper to the entire round surface of the dowel. when it dries, you’ve got yourself a rotary sander. you can just buy one of these if you want to skip the steps to here and you can often pick one up for a couple of bucks but not everyone wants to do that so this is how you make one rather quickly.

with that spinning in your drill, clamp the drill to your bench — i use a vise but you can just use clamps if you don’t have a vise. wait a second — you don’t have a vise? this may not be the time to make a fishtail chisel. this might be a time to make a vise. ok. no more tangents. make sure you can run the drill without it moving. now take your bench-chisel and slowly press it against the spinning wheel so the end of the blade ends a few millimeters from the point where the circle comes out the side. if the steel gets warm, stop for a few seconds for it to cool. don’t rush. when you get one side done, do the other side. you should end up with a profile that looks like this…

this is not the traditional profile for a fishtail chisel but it should be perfectly-fine for what you’re doing. you can always grind another half-circle of use a metalworking file to take away more steel and taper the whole thing back to the shaft or the handle. but what you’re trying to do is get the walls of the blade away from where they can interfere with your dovetail sockets and a circle with a 40mm diameter is likely to do it. if you do bigger dovetails, use a bigger dowel or file back more of the edge once you have the shape in.

one of the nice things about doing this with an old chisel is you can usually pick those up for only a few bucks so if you mess it up you haven’t really lost anything. yes, there is definitely a risk of warping or snapping the chisel but, having done this many times, i’ve never encountered it. the theoretical risk exists but you’re practically keeping 6-8mm in the center of the blade and that’s definitely strong enough. don’t worry too much if the fishtail profile isn’t centered. it doesn’t matter. you’re not using this to actually shape anything, just to clean waste from one side or the other. the handle being exactly in the middle of the tail is irrelevant to its usefulness, though it does look nice if you’re careful so you should probably at least try to get the two sides to match fairly closely.

once that’s done, simply hone an edge on your new fishtail-chisel exactly the same way you do a bench-chisel — it is, practically-speaking, just a bench-chisel that’s been pinched really hard by some overwhelmingly-strong fingers, after all.

i think i’ve had three people ask me about fishtails this week alone so it seems to be on everyone’s minds lately. hopefully this has at least given you something to think about and maybe you, too, can have a fishtail in your shop and no longer just have the spirits of the trees keeping you safe but have suijin (水神 — mythical water spirit) on your side? whatever you’re working on today, i hope it goes … swimmingly. thanks for taking the time to dive into this with me.